Conduct Cummins Engine Service and Repairs at Your Own Home or Workshop

Working on Cummins engines can be a rewarding and cost-effective endeavor, whether you’re a seasoned mechanic or an enthusiastic DIYer. With the right knowledge and tools, you can perform routine maintenance and address common issues right at home or in your workshop. This article provides an overview of Cummins engines, essential tools needed for repairs, a step-by-step guide for maintenance, and tips for troubleshooting. For comprehensive guidance, refer to Cummins Manuals.

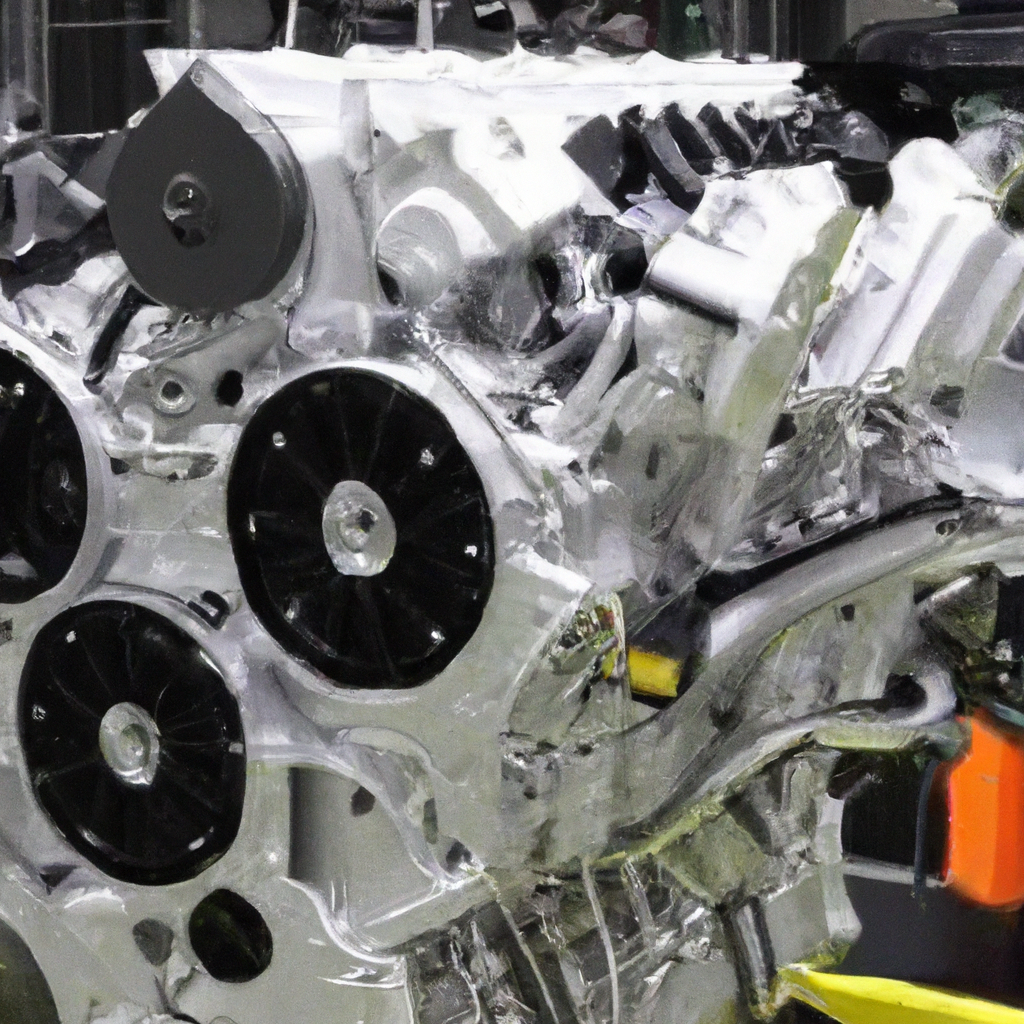

Understanding Cummins Engine Basics and Components

Cummins engines are renowned for their durability, efficiency, and power. To effectively service and repair these engines, it’s crucial to understand their basic components. The engine consists of several key parts, including the cylinder block, pistons, crankshaft, camshaft, valves, and fuel system. Each component plays a vital role in the engine’s operation, and having a grasp of their functions will aid in diagnosing and addressing issues.

The fuel system of a Cummins engine is particularly important, as it ensures that the engine receives the right amount of fuel for optimal performance. This system includes components such as fuel injectors, fuel pumps, and fuel filters. Being familiar with these parts and their operation can help you identify problems like fuel leaks or clogged injectors.

Cooling and lubrication are also critical aspects of Cummins engines. The cooling system comprises the radiator, water pump, and thermostat, which work together to prevent the engine from overheating. Meanwhile, the lubrication system ensures that all moving parts operate smoothly, minimizing friction and wear. Regular checks and maintenance of these systems are essential for engine longevity.

Finally, understanding the electrical system of a Cummins engine is vital. This system includes the battery, alternator, and starter motor, all of which are necessary for starting the engine and maintaining electrical functions. Familiarity with these components will make it easier to troubleshoot starting issues or electrical failures.

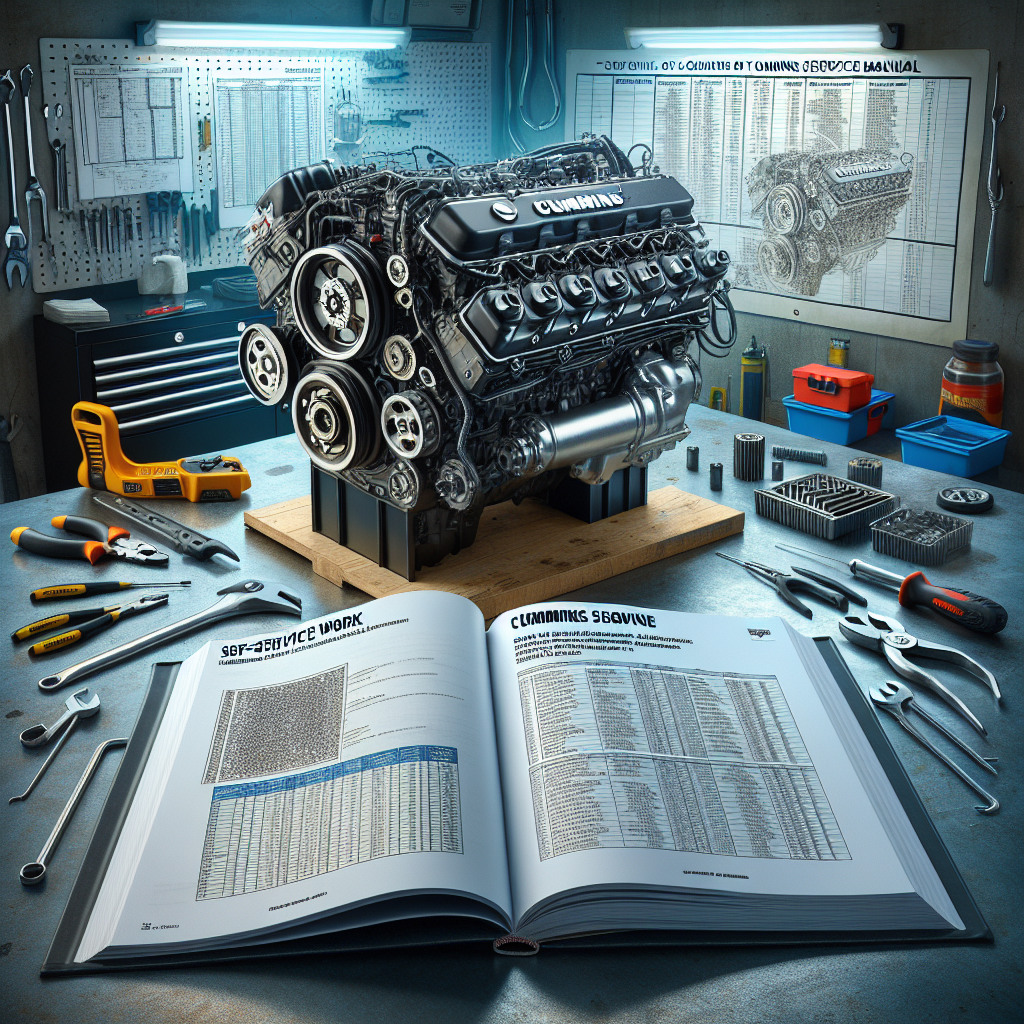

Essential Tools for Home and Workshop Repairs

To conduct effective Cummins engine service and repairs, a well-organized set of tools is essential. Basic hand tools such as wrenches, screwdrivers, and pliers are a must-have for any repair job. These tools will help you disassemble and reassemble engine components with ease. Additionally, a torque wrench is crucial for ensuring that bolts and nuts are tightened to the manufacturer’s specifications.

Specialized tools are also necessary for more complex repairs. A compression tester, for instance, is invaluable for diagnosing engine performance issues related to cylinder pressure. Similarly, a multimeter is essential for testing electrical components and ensuring proper voltage levels. Investing in these tools will make diagnosing and fixing problems more efficient.

For those who plan to perform extensive engine work, an engine hoist and stand can be extremely helpful. These tools allow you to lift and secure the engine for easier access to its components. This setup is particularly useful for major overhauls or when replacing significant engine parts.

Finally, having access to a comprehensive repair manual is indispensable. A repair manual, such as those available at Cummins Manuals, provides detailed instructions, diagrams, and troubleshooting tips specific to your engine model. This resource will guide you through complex repair procedures and ensure that you adhere to proper maintenance practices.

Step-by-Step Guide to Routine Engine Maintenance

Routine maintenance is key to keeping your Cummins engine running smoothly and efficiently. The first step in engine maintenance is conducting regular oil changes. Fresh oil ensures proper lubrication of engine components and helps prevent wear. Be sure to use the recommended oil type and change it at intervals specified in your engine’s manual.

Next, inspect and replace fuel filters as needed. Clean fuel filters are critical for maintaining optimal fuel flow and preventing contaminants from reaching the engine. Check the fuel filter regularly and replace it according to the manufacturer’s guidelines to avoid potential fuel-related issues.

Another important maintenance task is checking the cooling system. Ensure that the radiator is free of debris and that the coolant level is adequate. Inspect hoses and connections for leaks or cracks, and replace them if necessary. Maintaining the cooling system prevents engine overheating and extends its lifespan.

Lastly, perform regular checks on the air filtration system. A clean air filter improves engine efficiency and performance by ensuring that only clean air enters the combustion chamber. Replace the air filter as needed and keep the air intake system free from obstructions to maximize engine output and fuel economy.

Troubleshooting Common Cummins Engine Issues

Despite regular maintenance, Cummins engines may occasionally experience issues. One common problem is difficulty starting the engine. This issue can be caused by a weak battery, faulty starter motor, or fuel delivery problems. Begin troubleshooting by checking the battery charge and connections, and ensure that the fuel system is functioning correctly.

Another frequent issue is poor engine performance or loss of power. This can result from clogged fuel injectors, a dirty air filter, or problems with the turbocharger. Inspect and clean or replace these components as necessary to restore engine performance. Additionally, checking for error codes with a diagnostic tool can provide insights into underlying issues.

Excessive engine noise or knocking sounds are also concerns that require attention. These noises may indicate problems with the engine bearings, pistons, or valves. Performing a thorough inspection and using a stethoscope can help pinpoint the source of the noise. Addressing these issues promptly can prevent more severe engine damage.

Finally, overheating is a serious issue that should be addressed immediately. Overheating can occur due to a malfunctioning thermostat, a blocked radiator, or a failing water pump. Check these components and ensure that the cooling system is operating efficiently. Regularly maintaining the cooling system can help prevent overheating and protect the engine from damage.

Conducting Cummins engine service and repairs at home or in your workshop can be a fulfilling and cost-effective way to maintain engine performance. By understanding the basics of Cummins engines, assembling the right tools, following routine maintenance steps, and troubleshooting common issues, you can ensure that your engine runs smoothly for years to come. For detailed instructions and guidance, consider consulting Cummins Manuals, which provide valuable resources for both novice and experienced mechanics.