Cummins engines are renowned for their reliability, performance, and versatility across various applications. Whether you’re a seasoned mechanic, an engineer, or simply an enthusiast, having access to the right manuals can significantly enhance your understanding and ability to work with these engines. In this article, we’ll delve into the essential aspects of Cummins engine manuals, focusing on schematics, operation, maintenance, and service. For further details, you can explore resources available at Cummins Manual.

Comprehensive Guide to Cummins Engine Manuals

Cummins engine manuals are indispensable resources that provide extensive information about engine specifications, troubleshooting procedures, and detailed diagrams. These manuals are categorized by engine model and type, ensuring that users can find precise information tailored to their specific engine. The manuals typically include sections on safety precautions, technical data, and step-by-step instructions for various engine tasks. Whether you’re dealing with a heavy-duty truck engine or a smaller generator set, Cummins manuals are designed to cater to a wide range of needs.

The manuals are available in both print and digital formats, with the latter offering the convenience of quick searches and easy updates. The digital versions, often provided in PDF format, allow users to access information on-the-go, making them a popular choice among professionals in the field. These manuals serve as a comprehensive guide, covering everything from initial setup and operation to advanced troubleshooting and repair procedures.

One of the standout features of Cummins engine manuals is their detailed illustrations and diagrams. These visuals aid in understanding complex mechanical layouts and component interactions, which can be crucial when diagnosing issues or performing maintenance tasks. The manuals are designed to be user-friendly, with clear language and logical organization that helps users quickly find the information they need.

For those seeking further assistance or clarification, Cummins offers additional support through their website and customer service. By visiting Cummins Manual, users can access a wealth of resources, including downloadable manuals, FAQs, and contact information for expert advice.

Understanding Cummins Engine Schematics PDF

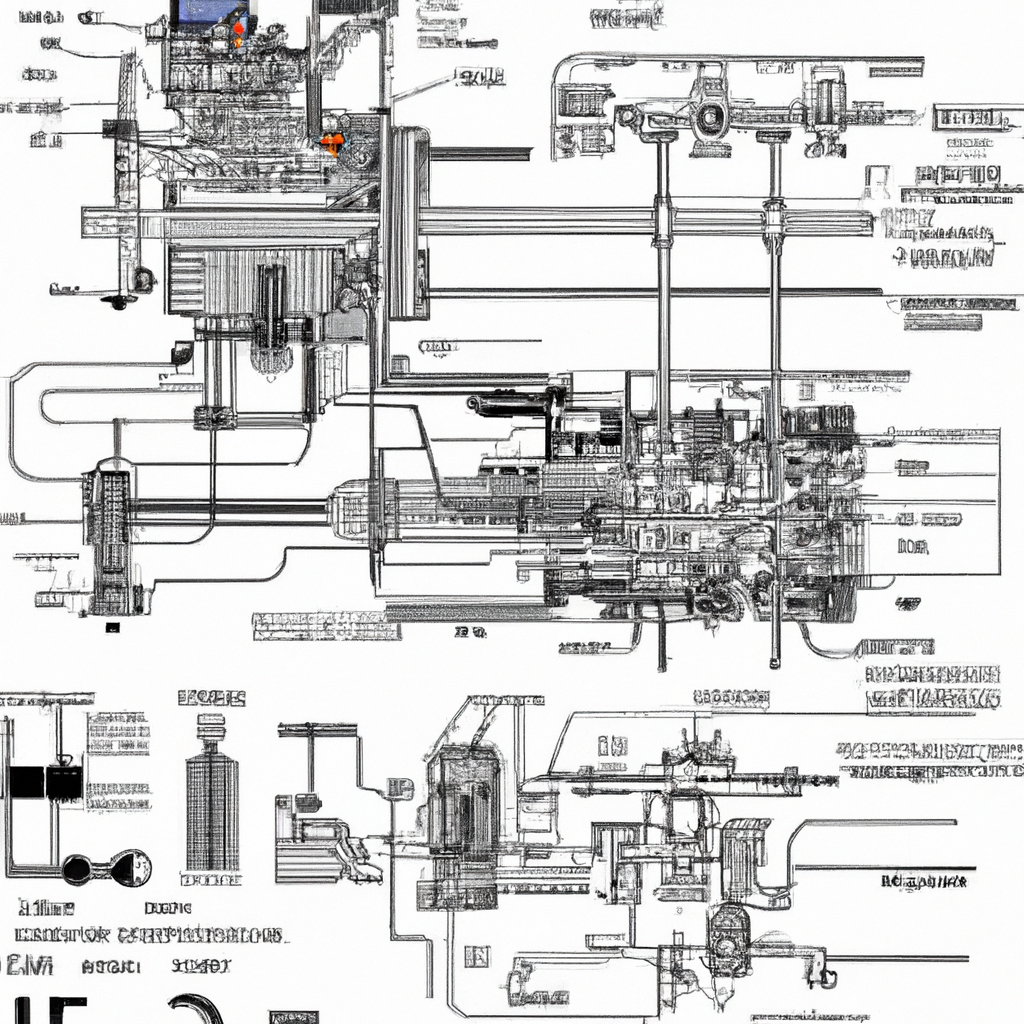

Cummins engine schematics are critical tools that provide a visual representation of the engine’s electrical and mechanical systems. These schematics are essential for anyone involved in the repair, maintenance, or modification of Cummins engines, as they offer a detailed map of the engine’s internal workings. The schematics are usually included in the engine manuals and are available in PDF format for easy access and printing.

The schematics cover various systems within the engine, including the fuel system, electrical wiring, cooling system, and exhaust system. Each schematic is meticulously detailed, showing the connections between components and the flow of power or fluids. This level of detail is invaluable for diagnosing issues, as it allows users to trace systems and identify potential problem areas with precision.

Understanding these schematics requires a basic knowledge of engine systems and symbols, but the manuals often include a legend or key to help users decipher the diagrams. For those new to engine schematics, taking the time to study these resources can greatly enhance one’s ability to perform effective repairs and modifications.

Accessing Cummins engine schematics in PDF form is convenient and beneficial, especially for professionals who need quick access to information in the field. By visiting Cummins Manual, users can find a range of schematics tailored to different engine models, ensuring they have the right resources for their specific needs.

Operation Insights: Cummins Engine Manual Details

Operating a Cummins engine efficiently requires a thorough understanding of its components and systems, as outlined in the engine manuals. These manuals provide detailed descriptions of engine operation, covering everything from starting procedures to optimal running conditions. By familiarizing themselves with these details, operators can ensure that the engine performs at its best, delivering reliable power and efficiency.

The operation section of the manual includes vital information on engine controls, instrumentation, and safety features. It outlines the correct procedures for starting, running, and shutting down the engine, as well as tips for optimizing fuel consumption and minimizing emissions. This information is crucial for both new users and experienced operators looking to refine their skills.

In addition to basic operation, the manuals often delve into more advanced topics such as engine tuning and performance optimization. These sections are designed for users who want to get the most out of their Cummins engine, providing insights into adjusting engine parameters and understanding performance metrics. By leveraging this information, operators can tailor engine performance to suit specific applications and conditions.

For comprehensive operation insights and detailed manual sections, users can refer to the resources available at Cummins Manual. This site offers a wealth of information, including downloadable manuals and expert advice, ensuring that operators have the tools they need to maximize engine performance.

Maintenance and Service Tips for Cummins Engines

Regular maintenance and timely service are crucial for ensuring the longevity and reliability of Cummins engines. The engine manuals provide a detailed schedule of maintenance tasks, outlining the intervals at which components should be inspected, serviced, or replaced. Adhering to these guidelines can prevent costly repairs and downtime, keeping the engine running smoothly.

The maintenance section of the manual covers a wide range of tasks, from routine oil changes and filter replacements to more complex procedures like valve adjustments and injector servicing. Each task is accompanied by step-by-step instructions and safety precautions, ensuring that users can perform maintenance confidently and effectively. The manuals also include troubleshooting guides to help users identify and rectify common issues.

Service tips in the manuals often include recommendations for using genuine Cummins parts and fluids, which are designed to meet the specific requirements of the engine. Using the correct parts and fluids can significantly impact engine performance and longevity, making it a key consideration for maintenance and repairs. The manuals provide part numbers and specifications to assist users in sourcing the right components.

For those seeking additional guidance on maintenance and service, Cummins Manual offers a range of resources, including expert advice and access to professional service networks. By utilizing these resources, users can ensure that their Cummins engines receive the care and attention they deserve, maximizing performance and extending service life.

Cummins engine manuals are invaluable resources that provide comprehensive insights into schematics, operation, maintenance, and service. By leveraging these manuals, users can enhance their understanding and capabilities, ensuring that their engines operate efficiently and reliably. Whether you’re a professional mechanic or a DIY enthusiast, having access to the right information is crucial for success. For more detailed manuals and expert support, visit Cummins Manual, where a wealth of resources awaits to assist you in your endeavors with Cummins engines.